Settings

Deliver to: () US

Change delivery settings

English

English

Categories

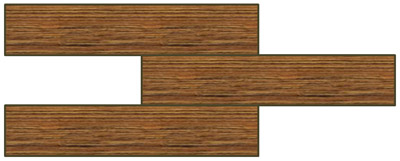

Flooring

Wall Coverings

Bathroom

Pools

Garden

Heating

Décor

Construction Materials

Super Deals

Customer Service

Contact us

Request a quote

Sample shipping

Selection by Styles

Selection by Room

Ceramic Skirting Boards

Coating Styles

New in ceramics

Bathroom sinks

Bathroom furniture

Bathroom mirrors

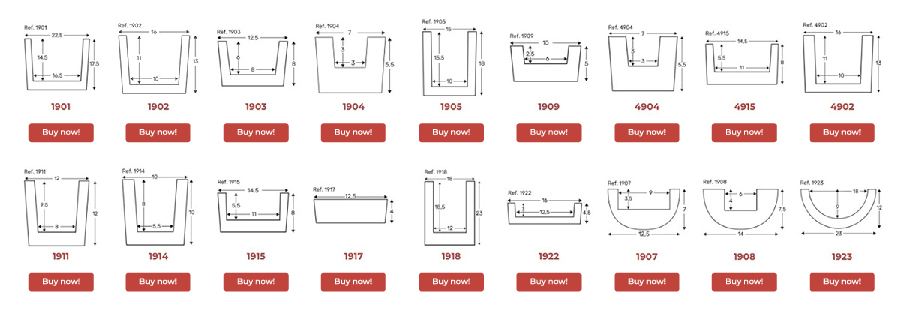

Coping edges for pools

Garden gardener amenagement

Garden accessories

Offers - Fireplaces and Stoves

Flue Pipes for Stoves and Fireplaces

Water Heaters and Boilers

Underfloor Heating

Furniture

Finishes

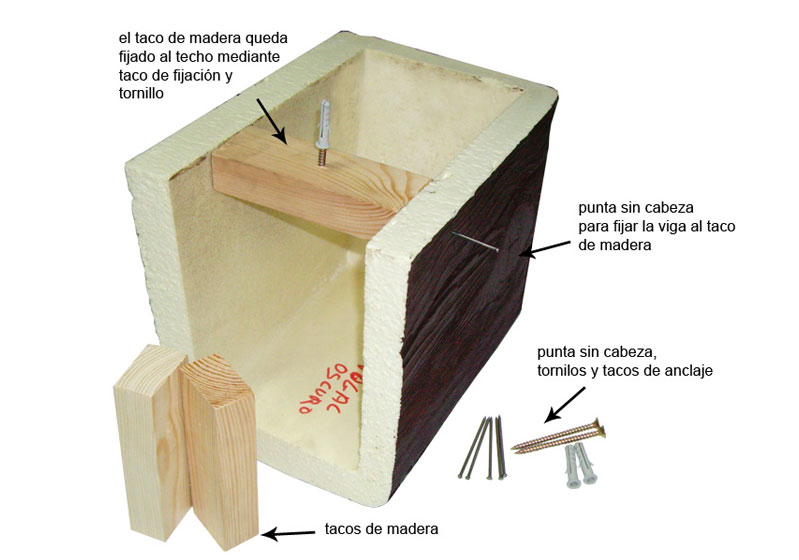

Rustic decor

Insulation and Waterproofing

Tooling

Tools

Construction

Shopping cart

Prices without taxes.

Prices without taxes.

There are no products in your cart right now.

Quantity

0 products

Total without VAT

0,00 €

Compartir

Enseña este producto a quien tú quieras.

Enseña este producto a quien tú quieras.

Compartir producto

Discounts of up to 30% during the long weekend