Instructions for installing WATER-STOP in swimming pools

General conditions for the installation

Waterproofing work should not be carried out when weather conditions may be harmful, in particular when it is snowing or there is snow or ice on the substrates, when it rains or the surface to be treated is wet.

Work should also not be carried out when the ambient temperature or that of the substrate exceeds the limits recommended for each product by its manufacturer (see data sheets for each product).

In interruptions in execution, the materials must be adequately protected.

Before starting or resuming the installation of WATER-STOP, it must be checked that the substrate meets the necessary conditions indicated in section C. Otherwise, the necessary time must be waited or adjusted.

It is necessary to protect the WATER-STOP sheet by placing panels in the circulation areas for any pedestrian circulation on the sheet until the final protection is placed.

Chronology of the works

The proposed order is the one that we consider to be the most appropriate in general, but the one that best suits the conditions of the installation will be appropriate:

- Inspection and preparation of the base support.

- Preparation and treatment of through-elements.

- Approaching, cutting and marking of WATER-STOP sheet cloths.

- Application of WATER-STOP on the walls.

- Sealing of joints and reinforcement treatment of singular points on walls.

- Placement of wall cladding.

- Application of WATER-STOP on the bottom.

- Sealing of joints and reinforcement treatment of singular points on the bottom.

- Placement of the bottom lining.

Conditions and preparation of the support

It is the responsibility of the installer to check that the conditions are in accordance with the following: The surface of the base support must be completely smooth and uniform, set and dry, without peaks, gaps or coques, edges or protrusions greater than 1 mm and free of foreign bodies. The flatness tolerance is 5 mm with the 2m ruler.

- C.1. Check for subsidence or differences in nivel, lack of cohesion or fissures.

- C.2. In the case of installation on old supports, inspect the support by means of a visual and, if applicable, sound (hollow sound) examination to determine the areas of the old coating to be preserved, treated or removed. Check for subsidence or differences in nivel, lack of cohesion, cracks, poorly adhered or broken pieces.

It is then prepared. Repair and sanitize with appropriate structural repair mortar. If the old coating is to be preserved, prepare by plastering, leveling or surface treatment by applying primer if the type of support requires it.

Dust carefully just before installation of WATER-STOP.

Through-element processing

Before Treating, deliveries to drains, spotlights, skimers, nozzles and other through-elements. A reinforcement of the waterproofing must be carried out at the mouth and around the element by about 15 cm. To do this, make a reinforcement piece with WATER-STOP sheet on site as indicated :

- Cut the necessary WATER-STOP pieces of the appropriate dimensions and shapes for the element to form a lining of the inside of the hole if possible and a piece that covers the front and surrounds it by about 15 cm.

- Apply the inside of the hole first by gluing the piece with WS BUTIL sealing tape, with adhesive putty and sealant type W-S MASTIC, or with waterproof and elastic cement. Press firmly taking care to remove the air underneath.

- Then apply the front piece, fixing it in the same way as in the previous step. With the help of a cutter or scissors, make several cuts from the center until you reach the perimeter of the embouchure, fold into the hole and glue.

Note: This system requires special care since during the curing time of the adhesives it is necessary to avoid tensions or movements that could damage the watertight seal.

- When the main sheet is passed over these reinforcements when placing it, before gluing it, a hole is marked and cut as close as possible to the element and much smaller than the quadrant. Use adhesive sealant putty or waterproof and elastic cement to glue the sheet over the reinforcement.

- Once the general installation is finished, the delivery of the membrane to the embedded elements is completed. The edge of the membrane in contact with plastic or metal must be sealed with epoxy putty suitable for use in swimming pools.

Approach

The sheet cloths are presented and cut to the necessary size and shape to cover the surface with anticipation of the floor on the wall and the wall overlap on the floor. Delivery areas are marked and prepared for individual points and through elements.

Foil Placement

As the formation of the waterproofing membrane with WATER-STOP is the most important element of the waterproofing system, its installation must be carefully taken care of.

The foil is glued to the support on its entire surface. The waterproofing membrane is formed by bonding WATER-STOP sheets together. When passing over a quadrant for the treatment of elements, proceed as indicated in section D.

Installing the film on the walls

The wall sheet must overlap the floor by no less than 10 cm.

The corners and angles are adjusted by cutting towards the vertex and gluing the sheet on itself with W-S MASTIC or W-S BUTIL putty.

To reduce the number of joints, it is advisable to apply the sheet taking advantage of the width of 2 m for the height of the wall in all the area where this is possible (maximum 180 cm + delivery to crown and overlap).

In the case of first making the walls to preserve the floor, it must be taken into account that the sheet to be installed on the floor has to rise no less than 10 cm on the walls under the sheet of these, so the 10 or 15 cm of the base of the walls must be left unglued for the time being.

Delivery on the top will preferably be made under the crowning pieces. If this is not possible, the edge of the sheet will be carefully sealed with epoxy putty suitable for use in swimming pools.

Installing the foil at the bottom of the beaker

The bottom sheet must be at least 10 cm high on the walls.

The corners and angles are adjusted by cutting towards the vertex and gluing the sheet on itself with W-S MASTIC or W-S BUTIL putty.

Make steps

The escalera is made with a piece that covers the esca lones like a carpet.

On the walls, the sheet of each step must be extended by about 10 cm, from the tread upwards and from the riser to the front, forming a plinth. You have to make a cut at each vertex to allow the sheet to bend.

If it is necessary to make a joint between sheets, it is made to coincide at the foot of a step and overlapping on the footprint.

The sheet on the walls of the staircase is also cut at each vertex to adapt it to the shape and overlap horizontally and vertically on the tread and riser. This overlap is closed as indicated in section Hl.

Attaching the film to the support

To fix the sheet to the support, a cementitious adhesive (adhesive cement) qualified type C2 according to the UNE EN 12004 standard, preferably deformable (TE S2) and suitable for the support, will be used.

In the case of some supports (such as antique ceramics) it may be necessary to use primer to improve the grip of the adhesive cement to the support. It is important to verify that the manufacturer indicates the suitability of the adhesive cement for the type of substrate in question or, if applicable, to use the associated primer indicated by the manufacturer.

The adhesive cement is applied to the substrate with the help of a notched trowel of at least 4 x 4 x 4 mm. In general, the approximate yield is 2 to 2.5 kg/m2.

It is necessary to follow the manufacturer's instructions for the preparation of cement glue.

- Present the first piece of the WATER-STOP sheet to be placed. Orient the cloth precisely and pull lightly to spread it well.

- Roll it up or fold it to clear the support area where the adhesive cement application will begin.

- Then apply the adhesive cement by spreading in sections and returning the sheet to its position to stick it by pressing with the help of the smooth side of the trowel towards the edge and taking care to remove the air underneath.

- Apply the following sheets with the same procedure.

- The process of gluing the film is the same in the application on the floor and on the walls.

For more comfortable installation when working with a format 2 m wide above the ground;

- Present the sheet piece and spread it out well Lift a side edge and fold it on itself in half the width of the sheet to clear the support area where the adhesive cement will begin.

- Then apply the adhesive cement by spreading in sections and returning the sheet to its position to glue it.

- Once glued along the entire length, lift and fold the other half wide and proceed in the same way.

- Once the installation of the waterproofing membrane with the WATER-STOP sheet is completed, the joints between the sheets are glued and sealed.

Joints and overlaps between sheets.

The joints between slats on both floors and walls are preferably made butt and cover joints with the help of W-S BUTIL and W-S BAND 14.

Each extended is arranged completely edge to edge with the adjacent one, without overlapping. The joints are covered with a strip of W-S BUTYL and the centred W-S 14 BAND IS PLACED on top of the butyl.

The placement of the pieces must be done in such a way that no joint between pieces of each extended is aligned with other joints.

The bonding and sealing of the joint cover strip and the overlaps will be carried out after the sheet has been placed on the entire surface.

Although it is not the preferred recommendation, the bonding and sealing of the joint cover belt can also be carried out by other means:

- Elastic waterproof cement one-component or two-component (see Note)

- W-S MASTIC adhesive and sealant putty (see Note)

As the bonding is not immediate, it is advisable to keep weight on the area during the time of setting of the adhesives (putty or cement) and it is necessary to avoid tensions or movements that could damage the watertight seal.

Bonding with W-S SUTIL adhesive sealing tape

- If necessary, remove dust and dirt from the sheet with a stiff brush.

- Place the W-S BUTIL tape on the joint with the protective paper facing up and apply pressure on the joint using a manual silicone roller or the smooth side of the trowel to expel any air that may be retained underneath.

Note: Pressing with the hand is not enough, it does not provide sufficient and uniform pressure to close the joint properly. Use a roller or other hard, blunt object to apply pressure.

- Place the W-S BAND 14 centered on the belt.

- Remove the protective paper by pulling from the tip perpendicularly in a regular way flush with the sheet in order to prevent air bubbles from entering. Face the entire length of the joint with your hand, as you remove the paper.

- Press the gasket with a manual roller above the belt and along its entire length, first through and then along its length.

- About 5 cm of the W-S 14 BAND will remain unglued on each side of the joint and then close them to the sheet with C2 adhesive cement.

- When it is necessary to splice lime tape, the next roll must overlap at least 25 mm.

- The overlaps on the ground and on steps are closed in the same way; with SUBTLE W-S applied inside the overlap and finished with glue cement.

Figure. Performing the overlap joint with W-S MASTIC putty

Binding by elastic waterproof cement.

- Prepare waterproof cement following the instructions on the product.

- With the help of a trowel or brush, apply the cement by spreading it in a layer of 1 to 2 mm thick in the area to be covered with the band.

- Cover with the band and press the trowel or trowel to the edge to remove air and achieve an even glue.

- Spread the protruding material on the sides of the belt or add material if necessary to form a 1 mm thick sealing layer over the edges of the already glued joint, taking care to smooth and not leave any enhancements.

- The estimated yield is between 200 and 350 gr per linear meter of belt.

Adhesive putty connection V sealant W-S MASTIC

- Prepare the cannula by cutting to have a bead diameter of 3 or 4 mm

- On each side of the joint line between sheets, apply a bead of putty and a second bead to further the outer edge of the area to be covered with the band.

- Apply another zigzag cord between them to obtain a larger contact surface.

- The cords must be continuous, in case of breaks or stops, resume the cord line from 1 cm before.

- Cover with the band and press the trowel or trowel to the edge to spread the material and achieve an even glue.

- Spread the material protruding from the band or apply a caulk bead if necessary to form a sealing layer over the edge of the already glued joint and with a moistened finger smooth it out.

- The estimated yield is 5 to 6 linear meters of overlap per 290 ml cartridge.

Other forms of joint construction

Although it is not the preferred recommendation, the joints between slabs can also be made by overlapping by means of a lap in favor of the slope in such a way that each extension overlaps the previous one by 5 to 10 cm.

The gluing and sealing of the overlaps between WATER-STOP sheets can be carried out by the same means described for the joint cover belt.

Review of critical points

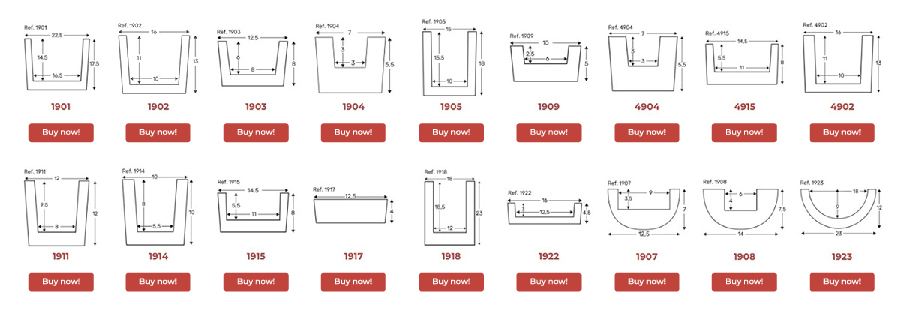

Finally, all the critical points are reviewed and the seal is reinforced with the help of W-S MASTIC, W-S BUTYL type putty or with waterproof cement if it has been used in the installation, applying patches made with cut-outs of the WATER-STOP sheet itself and W-S DEX and W-S DIN corners.

The seal of the delivery of the sheet to the crown, to the reinforcements of through elements and all joints is checked and ensured.

The corners and angles are patched over the vertices and covering any creases or cuts from the previous execution.

The encounters of the steps with the wall when they form 900 angles are patched using the W-S DEX outer corners on the overhangs and the W-S DIN inner corners on the inlets.

In addition to steps, corners are also used in the nooks and corners of the perimeter on the upper edges of overflow pools and at bottom-of-wall joints if they form regular angles of 90°.

The seal of the delivery of the sheet to the crown, to the through elements and to all the joints is checked and ensured.

Coating and commissioning.

Once the seal of the critical points has been reviewed and secured, the coating is installed directly on the sheet. Use cement glue (cement glue) qualified type C2 according to UNE EN 12004 standard preferably deformable (TE S2) and suitable for use in swimming pools.

Wait at least 24 hours for grouting After grouting the deliveries to through-and-socket elements, a final seal must be made.

Wait 5 days before filling the pool.