Pumafix TQP (Polyester Base) 300 ml Pack 12ud

€90.52

109,53 € VAT incl. 21%

109,53 € VAT incl. 21%

Receive it between 5 and February 6.

Calculate your shipping costs

Calculate your shipping costs

Select zone and quantity

Reference: 250300

Injection resin for anchors, bi-component and fast curing, based on polyester resin. Styrene free. Multifunctional: for both solid and hollow supports.

Table of Contents

Composition

Styrene-free unsaturated polyester resin.

Features & Applications

- Fixing horizontal and vertical chemical anchors.

- Suitable for solid and hollow supports.

- Styrene-free; low odor.

- Easy to extrude and injection.

- Thixotropic, can be applied in a horizontal or vertical direction.

- Fast curing.

- Applicable with conventional guns.

- It is used on concrete, bricks and hollow concrete blocks in a wide range of applications: fixing doors, railings, railings, blinds, awnings, antennas, signs, cable trays, industrial machinery....

Stands

- The supports must be resistant, stable, healthy and clean, free of dust, remains of release agents, organic products. They do not need to be 28 days old.

- If the condition of the support is unknown, it is recommended to perform pull-out tests to check the suitability of the support.

- Once the hole has been drilled into the support, clean any remains with compressed air or a cylindrical brush.

- Threaded rods and steel rounds must be free of oils, greases.

How to use

INSTALLATION INSTRUCTIONS IN SOLID MASONRY OR CONCRETE FACTORY

- By means of a drill machine make the hole with the diameter and depth according to the application table. During the drilling process, the perpendicularity of the hole in the bracket must be checked.

- Clean the hole of dust, fragments, oil, water, grease and other contaminants before mortar injection (with the manual blower and the standard manual brush).

- Cleaning the hole shall consist of at least 4 blowing operations, 4 brushing operations followed by at least 4 blowing operations.

- Before brushing, the brush should be cleaned and checked that the diameter of the brush is correct.

- The threaded rod must be free of dust, grease, oil or other impurities.

- Unscrew the cartridge cap, thread the mixing nozzle onto the cartridge, and place the cartridge in the gun.

- At the beginning of the use of a new cartridge, discard the injected product until a homogeneous color of the mortar is achieved.

- Fill the drilled hole evenly from the bottom to prevent occluded air by moving the mixing nozzle slowly outwards.

- Fill 2/3 of the depth of the drilled hole with mortar.

- Insert the threaded rod slowly and in a slight rotational motion, removing excess mortar injected around the threaded rod.

- Wait for the curing time according to the technical sheet.

- Do not move or load the anchor until curing is complete.

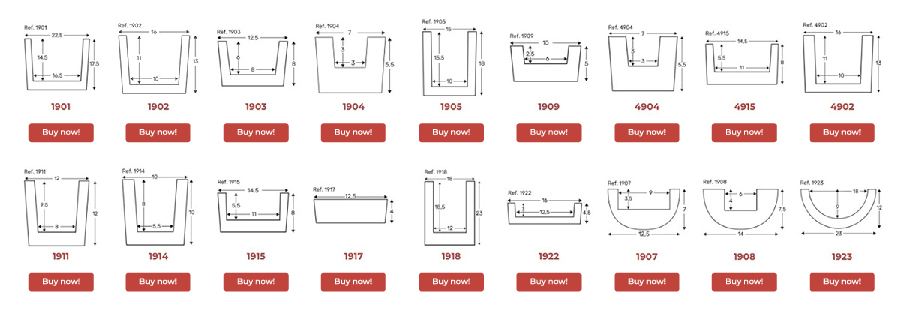

HOLLOW/PERFORATED MASONRY FACTORY INSTALLATION INSTRUCTIONS

- By means of a drilling machine make the hole with the diameter and depth according to the application table. During the drilling process, the perpendicularity of the hole in the bracket must be checked.

- Clean the hole of dust, fragments, oil, water, grease and other contaminants before mortar injection (with the manual blower and the standard manual brush).

- Cleaning the hole shall consist of at least 4 blowing operations, 2 brushing operations followed by at least 4 blowing operations.

- Before brushing, the brush should be cleaned and checked that the diameter of the brush is correct.

- The threaded rod must be free of dust, grease, oil or other impurities.

- Choose the correct sieve size.

- Unscrew the cartridge cap, thread the mixing nozzle onto the cartridge, and place the cartridge in the gun.

- At the beginning of the use of a new cartridge, discard the injected product until a homogeneous color of the mortar is achieved.

- Remove the cap from the plastic sieve.

- Insert the plastic sieve into the hole.

- Fill the sieve evenly from the bottom, moving the mixing nozzle slowly outwards: move the mixing nozzle 10 mm outwards each time the trigger is pressed.

- Completely fill the sieve.

- Put the cap on the filled plastic sieve.

- Immediately insert the threaded rod, slowly and with a slight rotational motion, removing the excess mortar injected around the threaded rod.

- Wait for the curing time according to the technical sheet.

- Do not move or shit the anchor until curing is complete.

| Product | Pumafix TQP (Polyester Base) 300 ml Pack 12ud |

| Brand / Manufacturer | Grupo Puma |

| Weight (kg) | 5 |

Reviews for Pumafix TQP (Polyester Base) 300 ml Pack 12ud

Do you need to know anything else?

What do you want to know about this product?

Send